Local DTF Printing revolutionizes apparel by enabling designers to create unique, personalized garments with high-quality prints using direct application onto fabric. This accessible method requires minimal investment and allows for vibrant colors and intricate designs on t-shirts, hoodies, and more. Mastering design techniques ensures optimal results, focusing on clean lines, minimal text, and high-resolution images, enhancing print vibrancy and precision.

“Unleash your design potential with an in-depth look at Local DTF Printing, a game-changer in the printing industry. This article equips every designer with the knowledge needed to navigate this vibrant, direct-to-film (DTF) technique. From understanding the basics and benefits of DTF Printing to exploring local setup requirements and advanced design strategies for exceptional outcomes, you’ll discover how this technology enhances your creative workflow. Embrace the future of printing with our comprehensive guide.”

- Understanding DTF Printing: Basics and Benefits

- Local DTF Printing: Setup and Equipment Requirements

- Mastering Design Techniques for Optimal Results

Understanding DTF Printing: Basics and Benefits

Direct to Film (DTF) Printing is a cutting-edge technique that has revolutionized the apparel industry, especially for local designers looking to create unique and personalized garments. This method allows artists to produce high-quality prints directly onto various materials, including t-shirts and hoodies, with exceptional precision and speed. By bypassing traditional printing methods, DTF offers designers a versatile and efficient way to bring their creative visions to life.

One of the key advantages of Local DTF Printing is its ability to deliver crisp, vibrant colors and intricate designs. It enables designers to achieve complex artwork, from subtle gradients to bold graphics, making it ideal for both simple and elaborate patterns. Moreover, DTF technology allows for direct application onto fabric, ensuring a smooth finish and exceptional durability. This process is particularly beneficial for creating custom hoodies with personalized messages or unique art, catering to the growing demand for distinctive, made-to-order clothing items.

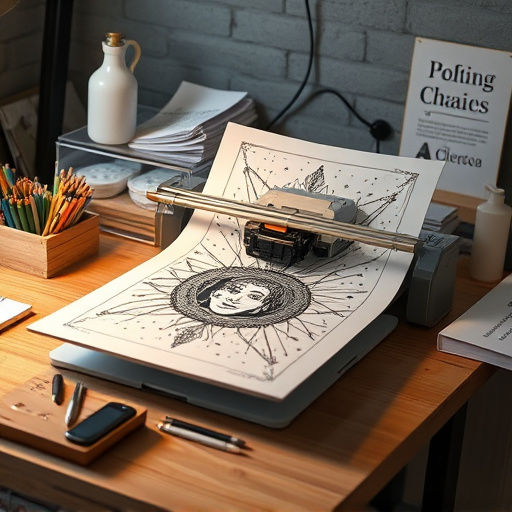

Local DTF Printing: Setup and Equipment Requirements

Local DTF Printing offers a unique opportunity for designers to create on-demand, personalized products with minimal setup and equipment requirements. To get started, designers need only a DTF (Direct-to-Garment) printer, heat press, and a computer with design software. The heat press is the workhorse of this process, allowing you to apply intricate designs to various fabrics with precision and speed. Once equipped with these essentials, the process becomes surprisingly accessible.

Designers can create or source their artwork, prepare it for printing using compatible software, and then load it onto the DTF printer. The machine transfers the design onto a thin film, which is subsequently heated and pressed onto the desired garment through the heat press. This method ensures high-quality results on a variety of materials, making it an attractive option for custom apparel, accessories, and more.

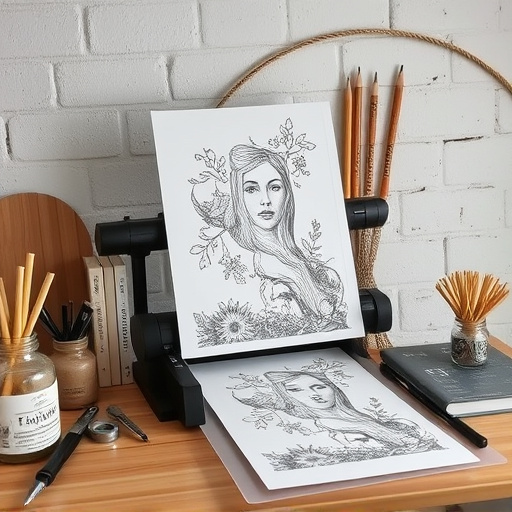

Mastering Design Techniques for Optimal Results

Mastering design techniques is paramount for achieving optimal results in local DTF printing. When creating designs for direct to film (DTF) prints, it’s essential to understand the unique characteristics of this process. Designers should focus on clean lines, minimal text, and high-resolution images to ensure the best dtf printer can reproduce details accurately. Using software that supports vector graphics and proper file formatting are crucial first steps.

Additionally, understanding color profiles and ensuring colors are correctly represented in the design will yield more vibrant and precise prints. Experimenting with different layout strategies, such as negative space utilization, can also enhance the overall aesthetic appeal of DTF prints. Ultimately, taking the time to refine designs for optimal compatibility with local DTF printing methods will result in superior-quality final products.

Local DTF printing offers designers a powerful, versatile tool for creating high-quality, on-demand products. By understanding the basics, equipping your studio with the right tools, and mastering design techniques, you can unlock the full potential of this innovative process. Embrace Local DTF Printing to elevate your creative workflow and cater to diverse client needs in today’s market.